I am a big fan of 3D printing and we use it in our lab all the time. But I am beginning to realize that many new users often don’t fully understand limitations of 3D printers and try to use them while they would have been much better served by using a laser cutter.

3D printing is inherently a slow process. This becomes obvious if you try to print a big part. If you are trying to make a large part and you want it quickly, then you might want to consider exploring laser (or waterjet) cutting instead. Let me try compare laser cutting with 3D printing with the example of a support bracket shown in Figure 1.

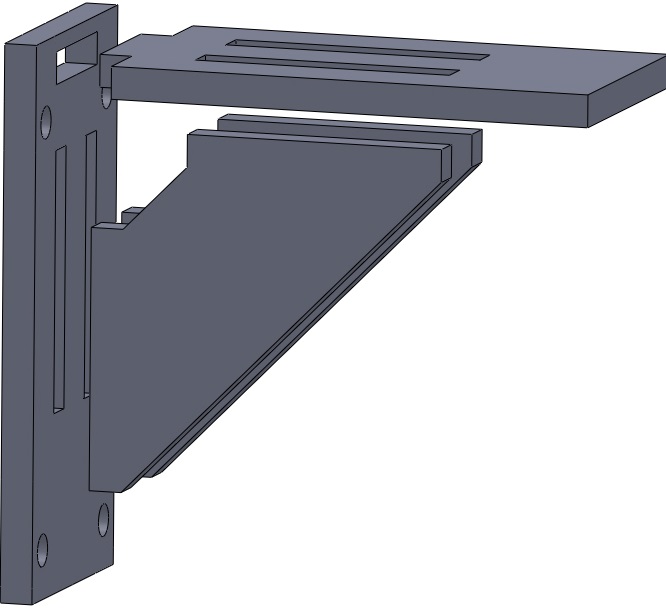

Figure 2 shows a 3D model of this bracket that you can make on a 3D printer. It will take several hours of printing time on a fused deposition modeling machine. You will also need to wait for many more hours for the support material to dissolve. Therefore, you will have to wait for an entire working day before you can get your bracket and start using it.

Laser cutting is a fast process that requires no setup time. Unfortunately, fast speeds in laser cutting are only available if you are cutting two dimensional profiles. You can cut pockets using raster cuts, but then the laser cutting process tends to be slow. For the bracket shown in Figure 1, you can simply design it to be a four piece assembly (shown in Figure 3). Each of the four individual parts can be simply cut as a 2D profile on a laser cutter in a few minutes.

If you can design the desired shape such that it can be assembled from parts produced by laser cutting two dimensional profiles, then you can realize your parts at a low cost and get them in a matter of minutes. You will be surprised by what can be realized by this simple process. For example, we have made several versions of legged robots using this process.

If you really need to make integrated 3D parts and it is not possible for you to convert your 3D model into an assembly of 2D parts, then you should go for 3D printing. For example, to build a robotic bird we decided to use 3D printing to make structural parts. Assembling a structural frame from small laser cut parts would have been simply impossible in this case, so 3D printing was the right choice in this case.

3D Printing or Laser Cutting? The answer to this question depends upon the part. 3D printing is a great process and the right answer in many cases. Laser cutting is process with remarkable capabilities, and you should think about it as an alternative to 3D printing. Laser cutting tends to be a lot faster and cheaper than 3D printing, but making it work requires creativity during design.

3D printing is inherently a slow process. This becomes obvious if you try to print a big part. If you are trying to make a large part and you want it quickly, then you might want to consider exploring laser (or waterjet) cutting instead. Let me try compare laser cutting with 3D printing with the example of a support bracket shown in Figure 1.

|

| Figure 1: Concept of a bracket |

Figure 2 shows a 3D model of this bracket that you can make on a 3D printer. It will take several hours of printing time on a fused deposition modeling machine. You will also need to wait for many more hours for the support material to dissolve. Therefore, you will have to wait for an entire working day before you can get your bracket and start using it.

|

| Figure 2: Bracket design that can be made on 3D printer |

|

| Figure 3: Bracket design as a four part assembly; each part can be cut on a laser cutter. |

If you really need to make integrated 3D parts and it is not possible for you to convert your 3D model into an assembly of 2D parts, then you should go for 3D printing. For example, to build a robotic bird we decided to use 3D printing to make structural parts. Assembling a structural frame from small laser cut parts would have been simply impossible in this case, so 3D printing was the right choice in this case.

3D Printing or Laser Cutting? The answer to this question depends upon the part. 3D printing is a great process and the right answer in many cases. Laser cutting is process with remarkable capabilities, and you should think about it as an alternative to 3D printing. Laser cutting tends to be a lot faster and cheaper than 3D printing, but making it work requires creativity during design.